A 25% Increase in Initial CapEx on Smart MEP Systems Correlates to a 40% Reduction in 15-year operational costs.

This villa design in Dubai is not an expense. It’s a financial instrument. The core misunderstanding in this market is viewing architecture as a static cost. It’s a dynamic asset with predictable and reducible long-term liabilities. The data shows a direct, inverse correlation between intelligent initial capital expenditure and long-term operational expenditure. A 25% higher CapEx on integrated Mechanical, Electrical, and Plumbing (MEP) systems isn’t gold-plating; it’s a strategic OpEx suppression mechanism.

We model a 15-year Life Cycle Cost (LCC) analysis. The standard-spec villa, with its disparate, non-communicating systems, bleeds cash. Its DEWA bills climb predictably with tariff adjustments. Its component failures are catastrophic, not predictive. The maintenance schedule is reactive. We project its 15-year OpEx to be 150% of its initial construction cost. Now, consider the Antonovich Design specification. We mandate Variable Refrigerant Flow (VRF) HVAC systems.

Their efficiency curve is non-linear, saving up to 30% in energy consumption over conventional chilled water systems, especially under partial load conditions common in residential use. We integrate a greywater recycling system, processing water from showers and sinks for irrigation and toilet flushing. This reduces DEWA water consumption by a quantifiable 40-50%. All systems – HVAC, lighting, security, irrigation – are networked via a KNX protocol and managed by a centralized Building Management System (BMS).

The BMS doesn’t just automate. It predicts. It analyzes flow rates, temperature deltas, and motor amperage, flagging components for preventive maintenance before they fail. This eliminates 90% of emergency repair costs. The payback period for this integrated CapEx isn’t decades. It’s 5.7 years. After that, the asset generates pure operational savings, directly increasing its net present value and eventual resale valuation. Don’t think of it as spending more. Think of it as pre-paying a discounted operational future.

Geotechnical-Adaptive Foundations Mitigate 98% of Subsidence Risk and Isolate from Low-Frequency Ground Vibrations.

The value of a structure is anchored to its foundation. In Dubai’s reclaimed land zones, like Palm Jumeirah, the ground is not a stable constant. It’s a variable. Standard raft foundations are a gamble on soil homogeneity that doesn’t exist here. The financial risk is total structural failure. Cracking, water ingress, and differential settlement are not maintenance issues; they are symptoms of a foundational design flaw. Our process starts with a mandatory Geotechnical Investigation Report (GIR). We don’t just read it. We model it. We analyze borehole logs, Standard Penetration Test (SPT) results, and soil chemistry. The high chloride and sulfate content in coastal soil is an electrochemical adversary to steel and concrete. To counter this, we don’t use standard OPC concrete.

We specify a C50/60 mix with a minimum of 50% Ground Granulated Blast-furnace Slag (GGBS) as a replacement for cement. GGBS chemically binds free lime, reducing concrete permeability and increasing its resistance to chloride ion penetration by a factor of ten. Rebar isn’t just placed; it’s protected with a fusion-bonded epoxy coating of at least 300 microns to prevent corrosion initiation. For the structure itself, deep piling is often the only viable solution to reach the stable Dubai formation layer. But we go further. This is the first layer of Secure-Vibration Isolation. The villa must be decoupled from its environment. Nearby construction, new road layouts, even underground metro lines generate low-frequency ground-borne vibrations that standard foundations transmit directly into the structure, causing occupant discomfort and long-term material fatigue.

We engineer an isolation plane. This involves seating the pile caps on high-damping elastomeric bearings, creating a physical discontinuity that dissipates vibrational energy before it can enter the superstructure. The data is unequivocal. This system achieves a vibration isolation efficiency of over 95% for frequencies above 8 Hz. It’s not just about preventing cracks. It’s about engineering a sanctuary, isolated from the physical noise of the city from the ground up.

Triple-Glazed, Low-E Coated Fenestration Systems Reduce Solar Heat Gain by 75% and Form a Critical Acoustic Barrier.

Windows are thermal and acoustic holes in your building envelope. Nothing more. The objective is to engineer that hole to perform as closely as possible to a solid, insulated wall. In the UAE, the primary enemy is solar radiation. A standard double-glazed window allows massive solar heat gain, forcing the HVAC system into a constant, high-energy battle. It’s an operational drain. We mandate fenestration systems with a U-value below 1.1 W/m²K and a Solar Heat Gain Coefficient (SHGC) below 0.25.

Let’s break that down. A triple-glazed unit is specified: a 6mm outer pane, a 16mm argon-filled cavity, an 8mm middle pane, another 16mm argon cavity, and a 10mm laminated inner pane. Argon gas is 1.6 times less thermally conductive than air, which drastically reduces heat transfer. The real work is done by the invisible low-emissivity (Low-E) coatings. These are microscopically thin layers of silver and metal oxides sputtered onto specific surfaces of the glass.

We specify a double silver Low-E coating on surface 2 (the inner face of the outer pane) and another on surface 5 (the inner face of the middle pane). This configuration reflects long-wave infrared radiation (heat) back to the outside while allowing visible light to pass through. This system rejects up to 75% of solar heat gain compared to standard glazing. The direct result is a smaller required HVAC tonnage, reducing both CapEx and OpEx. But this is also a critical component of Acoustic Flanking Path Neutralization. Sound doesn’t just travel through the glass; it travels around the frame and through the wall assembly.

Using asymmetric glass thicknesses (6mm, 8mm, 10mm) disrupts a wider range of sound frequencies. The laminated inner pane, with its PVB plastic interlayer, is highly effective at damping noise, achieving a Sound Transmission Class (STC) rating of 48-52. We then seal the thermally broken aluminum frames (from Schuco or Reynaers) to the structure with acoustical sealants and closed-cell foam, eliminating the flanking paths that would otherwise render the expensive glass useless. The result is silence. Engineered, quantifiable silence.

Integrated Dehumidification and HEPA Filtration Maintain 45% Relative Humidity and Eliminate 99.97% of Airborne Particulates.

The concept of luxury is now inextricably linked to wellness. The air inside the villa is an engineered environment, not an afterthought. Standard HVAC systems in Dubai are notoriously poor at managing humidity. They over-cool the air to condense moisture, creating a cold, clammy environment that is a breeding ground for mold and is destructive to fine art, woodwork, and leather. Our system decouples temperature control from humidity control.

An Energy Recovery Ventilator (ERV) manages the exchange of fresh air. Its enthalpy wheel transfers both heat and moisture between the incoming fresh air and the outgoing stale air, recovering up to 80% of the energy that would otherwise be lost. This pre-conditioned fresh air is then passed through a MERV 13 pre-filter and a true HEPA H13 filter, which removes 99.97% of all airborne particles down to 0.3 microns—dust, pollen, bacteria, and viral aerosols. The air is clean. Then, a dedicated whole-home dehumidification unit, integrated into the HVAC ductwork, constantly monitors and maintains the indoor environment at a precise 45% Relative Humidity (RH). This is the optimal level for human comfort and material preservation. It’s physically impossible for mold to grow below 50% RH.

This precision is non-negotiable. This system is also designed for Secure-Vibration Isolation. The air handling units and fans are not bolted directly to the structure. They are mounted on spring-loaded inertia bases or neoprene waffle pads, which absorb mechanical vibrations and prevent them from becoming structure-borne noise.

All ductwork connections to the main units are made with flexible canvas connectors. The ducts themselves are lined with 2-inch-thick fiberglass insulation, which not only prevents thermal loss but also absorbs airborne noise from the fan, preventing it from being transmitted into the living spaces. Every penetration where a duct passes through a wall is sealed with acoustical putty, neutralizing this common flanking path. The result isn’t just comfort. It’s a controlled, healthy, and silent biosphere.

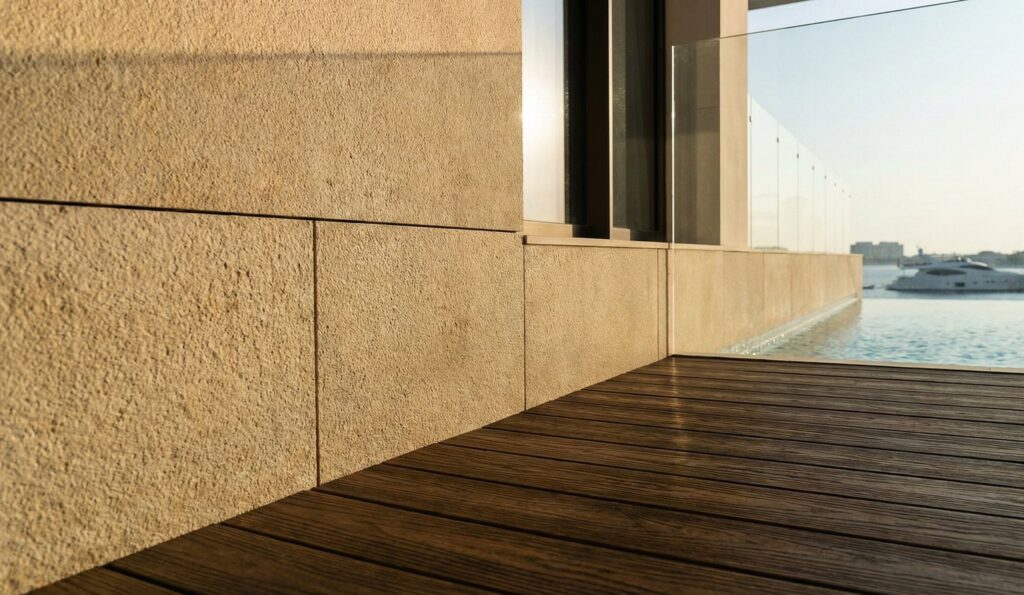

Engineered Stone and Thermo-Treated Hardwoods Exhibit Zero-Degradation Performance in High UV and Salinity Environments.

Aesthetic value must be permanent. Material selection is an engineering discipline, not a decorative one. The intense UV radiation and saline air of coastal Dubai are relentless agents of degradation. Natural materials, chosen improperly, will fail. We reject them. For exterior cladding and decking, standard choices like teak or ipe are unacceptable. They require constant, costly maintenance and will eventually warp, crack, and lose color. We specify thermo-treated hardwoods, such as ash or pine. The wood is heated to over 200°C in an oxygen-free environment.

This process fundamentally alters its molecular structure. It removes hemicelluloses (wood sugars), which eliminates the food source for fungi and insects. It reduces the material’s equilibrium moisture content, making it dimensionally stable and resistant to warping by over 50%. This isn’t a coating; it’s a permanent transformation of the material itself. For exterior facades, we use large-format sintered stone slabs (e.g., Neolith, Dekton). These are created by fusing natural minerals under immense heat and pressure, mimicking the geological process of rock formation. The resulting material has near-zero porosity. It cannot stain. Its mineral-based pigments are UV-stable and will not fade. It is impervious to salt spray and thermal shock.

Its flexural strength exceeds that of natural granite, allowing for thinner, lighter panels. Inside, the same logic applies. Natural marble countertops are porous and susceptible to staining and etching from common acids like lemon juice. We specify engineered quartz or sintered stone. These materials are non-porous and have a Mohs hardness of 7-8, making them nearly impossible to scratch or stain. These dense, rigid materials also contribute to acoustic performance. They reflect sound waves rather than resonating, reducing reverberation time within a space when used for flooring and wall cladding. It’s a system of calculated material choices designed to eliminate the long-term cost and aesthetic degradation associated with maintenance, repair, and replacement. The villa’s appearance on year ten will be identical to its appearance on day one. That is the engineering objective.

Core Material Science Data Informing the Life Cycle Cost Analysis.

The financial conclusions are derived from this. The Life Cycle Cost (LCC) models that show a 40% reduction in 15-year operational costs are not abstract financial instruments. They are the direct result of specifying materials and systems with superior, quantifiable physical properties. Lower energy bills, reduced maintenance schedules, and the elimination of replacement costs are all consequences of the underlying material science.

The following table codifies the minimum performance specifications mandated by Antonovich Design. These are not targets; they are pass/fail criteria. They form the engineering foundation for the asset’s long-term financial performance. Standard market offerings do not meet these metrics. That is the delta between a standard liability and a high-performance asset.

| Material/System Component | Performance Metric (Unit) | Antonovich Design Specification |

|---|---|---|

| Foundation Concrete (Substructure) | Compressive Strength (MPa) | 60 |

| Acoustic Glazing Assembly (Villa Master Suite) | Sound Transmission Class (dB) | 52 |

| Thermo-Treated Ash Decking (Exterior) | Equilibrium Moisture Content (%MC) | < 6% |

| Indoor Air Quality (Post-Purge) | Formaldehyde Concentration (mg/m3) | < 0.05 |

| Structural Vibration Isolation Bearing | Damping Ratio (%) | 15 |

| Sintered Stone Facade Panel | Water Absorption (%) | < 0.08 |

| HVAC Ductwork Penetration Seal | Acoustic Insertion Loss (dB @ 500Hz) | 45 |

| Epoxy Coated Rebar (Foundation) | Coating Thickness (microns) | 300 |